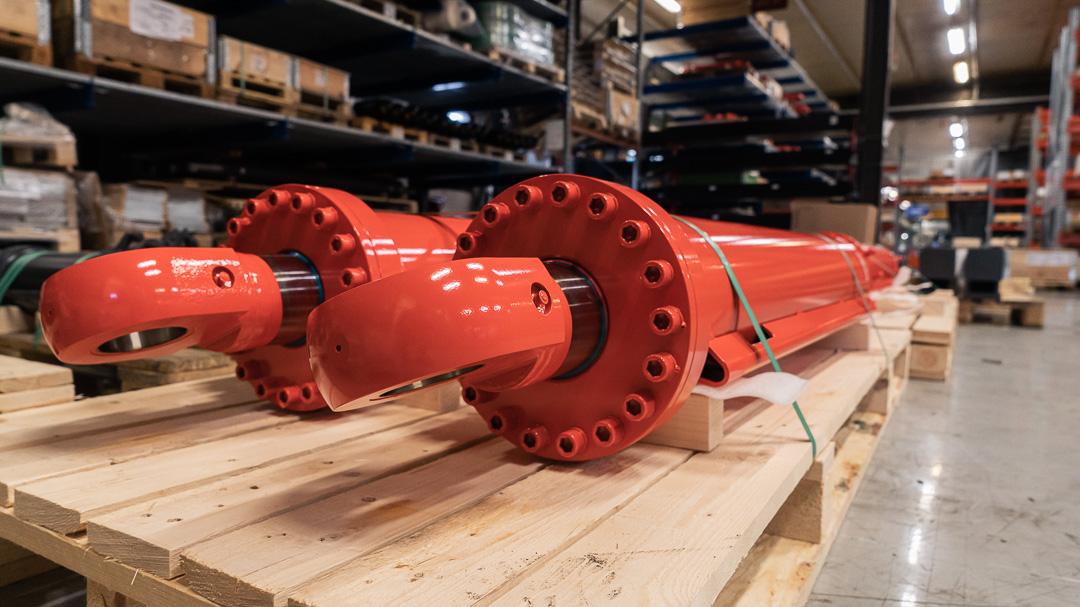

Hydraulic cylinder contract manufacturing

Hydraulic cylinder contract manufacturing is a partnership that benefits both parties: the OEM customer and the hydraulic cylinder manufacturer. It offers a trusting relationship, which in turn helps to achieve the best possible results. At Hydroline, we always pursue to build long-lasting and mutually beneficial cooperation with our OEM customers. We are a value-adding partner with a desire to offer our customers the best tools and hydraulic cylinders to make their business as effective as possible.

At Hydroline, we aim for long and mutually beneficial partnerships. That is why we are always happy to mention that our oldest contract manufacturing clients date back to the 1970s. We work closely with global leading mobile work machine OEMs (original equipment manufacturers) in multiple different customer segments and we manufacture hydraulic cylinders for countless different needs. If you have taken a closer look at our page, you might have noticed that our main OEM customers segments are forestry, load handling, agriculture & maintenance, and mining & construction. In these segments we are proud to serve the hydraulic cylinder needs for customers such as Cargotec, Sandvik, Valtra, Epiroc and Normet, along with many more industry leaders.

🏭 Establishing a contract manufacturing partnership

Establishing a successful hydraulic cylinder contract manufacturing partnership involves a detailed process which ensures that both technical and cost-saving needs are met. The following outlines the key steps typically followed by an OEM when selecting and engaging with a hydraulic cylinder manufacturer. From identifying supplier capabilities to auditing, negotiations, and product approval, each stage is crucial to building a lasting partnership. At Hydroline, we typically begin with a three to five-year contract, which is then updated and extended as necessary to ensure long-term collaboration and continuous improvement.

Here is a typical process of establishing a contract manufacturing partnership:

1. The OEM / customer has technical or cost-saving needs

2. The OEM maps out the possible suppliers and their technical ability and costs

3. The OEM requests quotations and technical proposals

4. The OEM performs an audit

5. Contract negotiations

6. Product approval before serial production – sample products from the supplier

7. Contract approval and production ramp-up

🔍 Benefits of Contract Manufacturing

In our industry the production volumes are big. With contract manufacturing, an OEM gets the benefit of securing the acquisition of a great number of fully tailored hydraulic cylinders annually.

Because hydraulic cylinders are not standard “off the shelf” products, they typically cannot be bought just anywhere with a short delivery time. Therefore, a contract customer always has a hydraulic cylinder supplier for a specific cylinder they regularly need. At Hydroline, we pursue to find the best solutions in terms of technical quality and logistics solutions, such as delivery times, warehousing, and buffers.

One of the contract manufacturing advantages for an OEM is the quality workmanship of a familiar supplier that knows the component and the customer’s final product; be it an excavator, a harvested head for a forestry machine or a mobile crane. As a hydraulic cylinder supplier, we take care of the customer’s component manufacturing, and our customer can focus on their core competence, machine manufacturing. This also means that the customer has no need to invest in their own component manufacturing.

Another one of the benefits of forming a long-lasting partnership with a hydraulic cylinder manufacturer like Hydroline is that an OEM gets to use our expertise in all areas of our business, not only in cylinder manufacturing. We always strive to find the best possible holistic solutions by using our knowledge from, e.g., electric and electrohydraulic actuators to coating and IoT solutions in addition to designing and manufacturing hydraulic cylinders. And we are not only the experts of manufacturing but also repairing; in addition to our manufacturing business, our partially owned partner HL-Hydraulics offers repair and maintenance services for every hydraulic cylinder, despite the original manufacturer.

We truly take pride on ourselves on being flexible and responsive to our customer’s needs.

💎 Cooperation & Proprietary

Cooperation is the key to a successful partnership. Like the OEM is the expert on their final machine into which our hydraulic cylinder(s) will be integrated, we bring our expertise in our products and services to the table from start to finish. When we join forces, we can find the best possible solutions.

As a hydraulic cylinder partner, we aim for the closest possible cooperation in all aspects, from our customer’s product development to understanding their complete strategy. A big part of being an excellent hydraulic cylinder supplier is to continuously and proactively seek and provide information about more sustainable and cost-effective solutions and new technologies to our OEM customers that add value to them. In order to keep up with the latest industry trends and constantly be able to keep up with the global development, we also have built a well-structured supplier and partner network with whom we are able to come up with better solutions and innovations.

When a customer develops a new solution or device, we emphasize the importance of us being involved as early as possible in the development process. This way we can have as much influence as feasible on the final solution and find the optimal result. Our influence is much less if we are only involved in the design process at a later stage.

Hydroline’s longest hydraulic cylinder partnerships with the world’s leading OEMs have deep roots in the history, and many of our major customer relationships are over 20 years long. We commit to being our customer’s true partners in business development and technical improvement.

Maybe we are the right partner for you as well? If you are looking for a new hydraulic cylinder manufacturing partner, do not hesitate to contact us!

Want to read more from us?

Fully automated production line – the future of hydraulic cylinder manufacturing

21.10.2019

It is time to open a little bit about our project of our new automated manufacturing line for tubes and rods. The project kicked off..

Read moreSavroc TripleHard® chrome coating – revolutionizing sustainability and safety in manufacturing

24.01.2024

In the era where an increasing amount of attention towards environmental responsibility, sustainability, safety, and financial prudence are at the forefront of business considerations, the..

Read moreLEO: The predictive maintenance solution for hydraulic cylinders

27.06.2020

What is LEO, the predictive maintenance and monitoring solution for hydraulic cylinders? The project with LEO started already in 2013 when Hydroline presented the invention..

Read moreHydraulic cylinder manufacturing

11.03.2022

Like we have explained in our very first blog post, a hydraulic cylinder is one of the four main components of a hydraulic system. Hydraulic..

Read more