Hydraulic cylinder manufacturing

Like we have explained in our very first blog post, a hydraulic cylinder is one of the four main components of a hydraulic system. Hydraulic cylinders are used in various applications where a great amount of force is needed. At Hydroline, we manufacture hydraulic cylinders for several segments, our main ones being agriculture, mining & construction, forestry and load handling. We manufacture all our cylinders in-house in order to guarantee their reliability and compliance with the strict self-imposed parameters regulating the company policy. Starting all the way from design and engineering, we have tested and approved every single production step. Below are our steps for manufacturing hydraulic cylinders as per the demand of the customers.

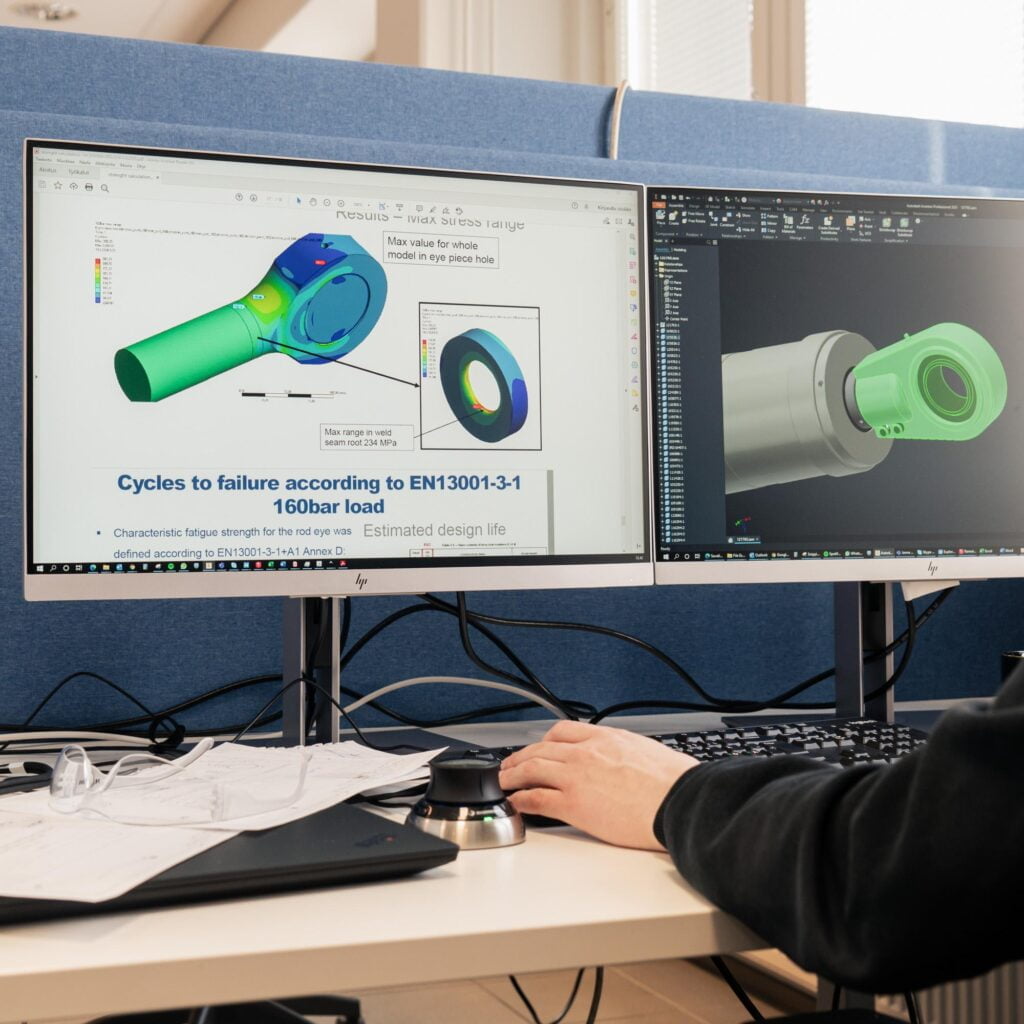

1. Hydraulic Cylinder Design

Hydraulic cylinders are somewhat complex devices; they contain a wide range of components available in a large number of sizes, configurations, and materials. However, at the same time, hydraulic cylinders are quite simple, as the main structure always remains the same. The greatest difference between cylinders and their different types, is faced when the design process is started.

Since the hydraulic systems are so complex, cylinder specification can be challenging for design engineers — as each design factor influences one or more of the many other design details that need consideration for the application. The cylinder is designed by a team of design engineers, taking into account the use of the hydraulic cylinder and the environment that it will be in. This dictates materials, coatings, seals and other specialist parts.

Hydraulic cylinders usually consist of a cylinder body, piston rod, and seals. All hydraulic and sealing components may have different requirements in terms of dimensional tolerances, surface roughness, shape and position tolerances. Since Hydraulic cylinders have many different working conditions, it affects the design criteria. For example, the cylinders used in the mining and construction machines versus in forestry, have other design criteria in terms of materials used.

If you want to learn more, what kind of information is needed for hydraulic cylinder design, go read our blog post about hydraulic cylinder’s initial data.

|  |

2. Materials & production planning

Selecting the right materials is a part of the careful design process. It is important to select the right steel material. There are three common materials used for hydraulic cylinders: # 20 steel; # 45 steel; Cr40 steel. # 20 that has the lowest hardness, is normally used for low-pressure hydraulic cylinders and used in places like excavators; # 45 steel and Cr40 are normally used in the high-pressure hydraulic cylinders with a 10000 psi rated working pressure.

When the design and materials has been approved, our engineering department starts making the more specific plans for production. Our engineering department makes sure we have all the needed tools are available at our factory. For example, we need to be sure we have the right kind of tools and expertise for machining. Sometimes we need to write down new instructions in case some part of the manufacturing process is done in a completely new way. Our production needs to know just in what way the new products are required to be manufactured. Our engineering department also designs the production flow and phasing for the production for each product. They ensure that the new products go through our production in a right way.

Order desk takes care of planning the production. They make sure the needed capacity is available and schedules the production process accordingly.

3. Machining & welding

As already mentioned, hydraulic cylinders consist of multiple different parts and components. If you wish to deepen your knowledge on what is a hydraulic cylinder’s structure like, visit this blog post that explains what is a hydraulic cylinder.

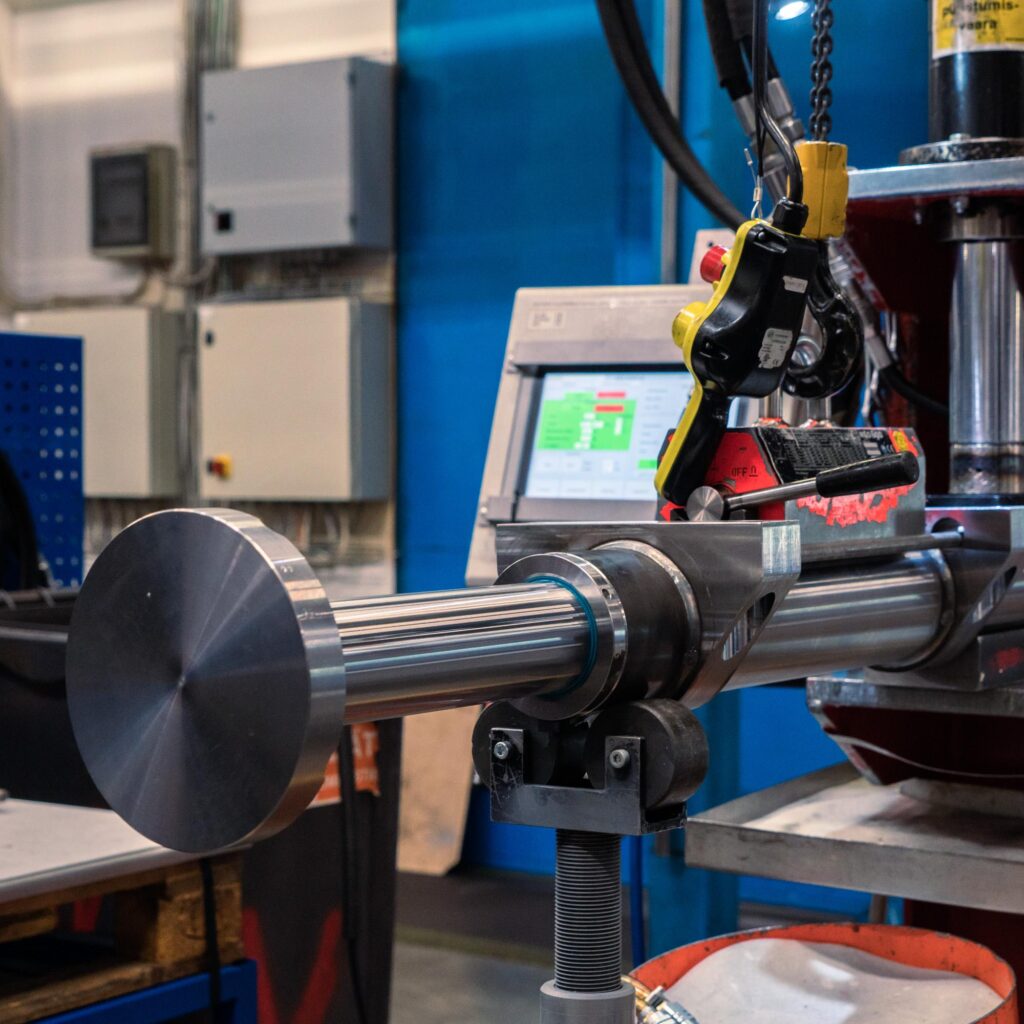

After careful planning, it is time to start working the actual manufacturing process. The process starts with raw materials and their lathing process into ready-to-use components. At Hydroline, we machine some of the components by ourselves at our factory. In some cases, for example, it is more cost effective and customer friendly to manufacture the components in-house rather than outsource their buying. In the machining process, the raw material part is lathed into a right shape. Our highly experienced and skilled workers take care of the machining. Machining as a task requires careful control and skills.

After the components are ready, inspected and washed carefully, it is time to move onto welding. Rod eyes are welded to the rod, tube ends to tubes.

At Hydroline, we also use friction welding for certain cylinder models. Friction welding is said to be the most cost-effective method of producing high integrity piston rod assemblies in high quantities. You can read more about our friction welding process here.

|  |

4. Collecting & Assembly

After every component is finalized, all the parts are collected from the warehouse and everything is inspected, it is time to start the assembly process. In the beginning of the assembly process, every part is carefully washed and protected. The purity level of each part is inspected. Washing results and washed parts are sampled daily and their cleanliness is checked. Hydroline’s washing machines’ washing solution cleanliness along with washing chemistry are also examined regularly. An ultrasonic cleaner is used for small and sensitive parts.

Hydraulic cylinder assembly process at Hydroline

- After all the components have been inspected and their cleanliness has been checked, the actual assembly process starts. First the seals are put in place (for piston, cylinder head etc.) along with bearing and snap ring.

- The piston is to the rod.

- The seals are oiled around the piston and cylinder head.

- After the rod is assembled with every component, the whole package is ready to be installed to the tube.

- During every step, the cleanliness is the top priority and at every point of the assembly, the surfaces are kept clean and properly wiped if necessary.

- The tube is also inspected visually and after that the tube is attached horizontally to an installation bench, a bearing is installed and the tube is oiled properly from inside.

- The rod is carefully slid inside the tube with the piston end first.

- The torque is set according to customer requirements.

- After the actual assembly of tube and rod is ready, the bearings and grease nipples are installed.

|  |

The proof testing and final inspection

After the cylinder is assembled, it is ready to be proof tested. The purpose of the testing, also known as proof test, is to ensure the safety and functionality of cylinders. The proof test is done with a pressure that is more than the actual usage pressure at the final machine, to ensure that all the joints and welds in the cylinder can take the pressure. The internal leaks can then be identified from the computer.

The valves are often installed to the cylinder after the proof test. This is because after the assembly, cylinders are “dry” and there is air inside them. During the proof test, the cylinder is filled with pressurized oil so cylinders must be emptied from the air; if the valves are in place, all of the air might not be able to escape from the cylinder.

If pressurized oil is pumped inside a cylinder that is filled with air, it causes a major security risk and might cause a serious accident. Some valves can be used during the proof test but in most cases not.

After the proof test, all testing documents are filled. These include both Hydroline’s own and the customers’ documents. Finally, the cylinders are ready for painting and the tester also attaches protective covering to the cylinders for painting. One of the main tasks in hydraulic cylinder manufacturing is to make sure the cylinders work like they should. When the final inspection is being done, all standards are measured.

5. Painting

After testing, the painting, coating and polishing is done. All the cylinders have an under coat, mid coat and top coat of paint. The paint is sprayed onto the body of the cylinder in order to keep it watertight and prevent it from rusting. Just like everything else, the painting and other surface treatment is always done according to customer needs.

6. Packing and delivery

Finally, the cylinders are packaged and shipped as per the customer’s needs and orders. Some cylinders go directly to our customer’s assembly line as some of them are delivered to customers’ warehouses as spare parts.

|  |

The future of hydraulic cylinder manufacturing is here

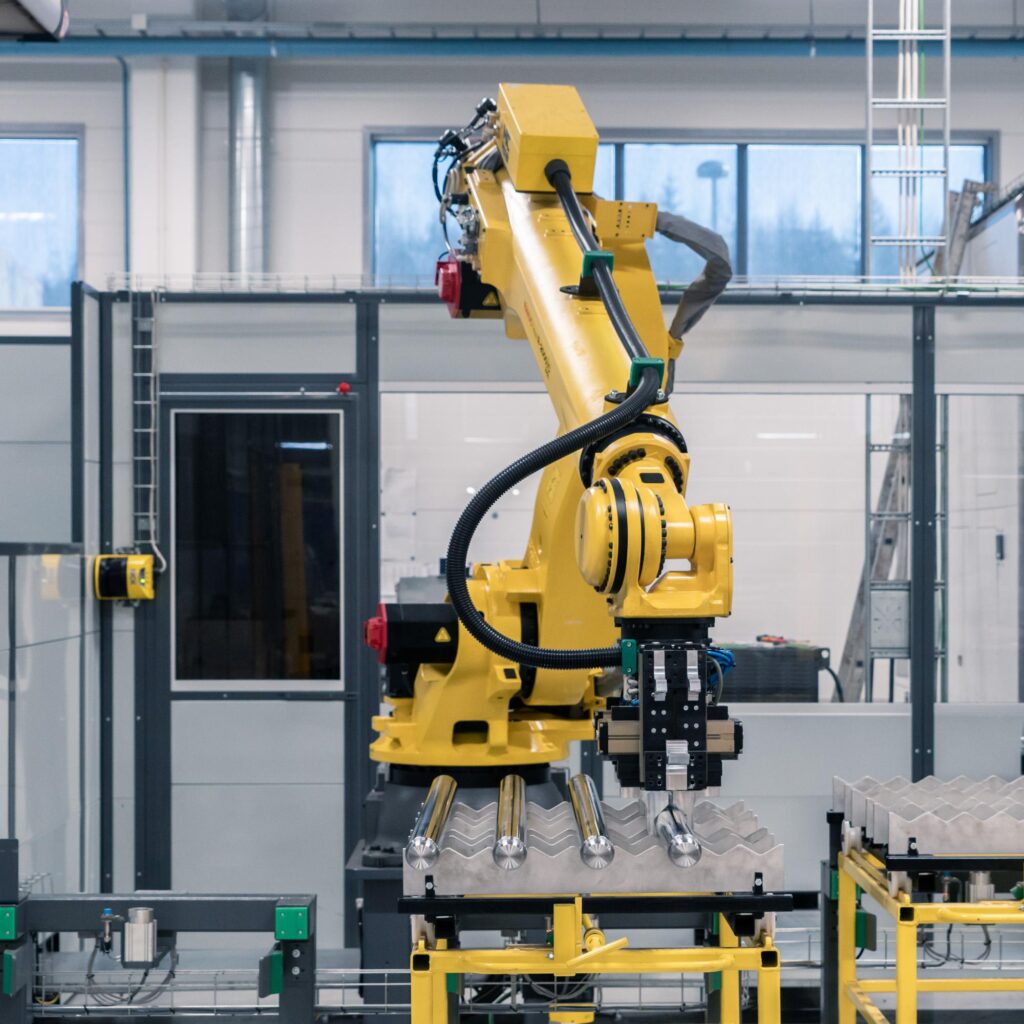

Automation in hydraulic cylinder manufacturing is still relatively unknown and new. However, we want to be the ones to change this idea and show that hydraulic cylinder manufacturing can be automated as well.

The new line offers more service abilities and a manufacturing chain that will benefit our customers. With our new production line, we are able to react faster to our customers’ needs; and also, increase our ability to adapt to changes. Of course, this line is not the only solution for everything, but we strive for an even more efficient way of working.

Our employees have been going through a massive education process about the products, manufacturing methods, programming of the robots, and controlling the system. The routines of working at the automation line are quite different compared to traditional welding and machining tasks. Also, from the company’s point of view, this offers a career path for the employees. The work task profile is different from the traditional manufacturing of tubes and rods, but it is based on that. Large elements are increased in the work tasks as the machinist and welder become operators for the robots.

|  |