A LEADING EXPERT OF CUSTOM

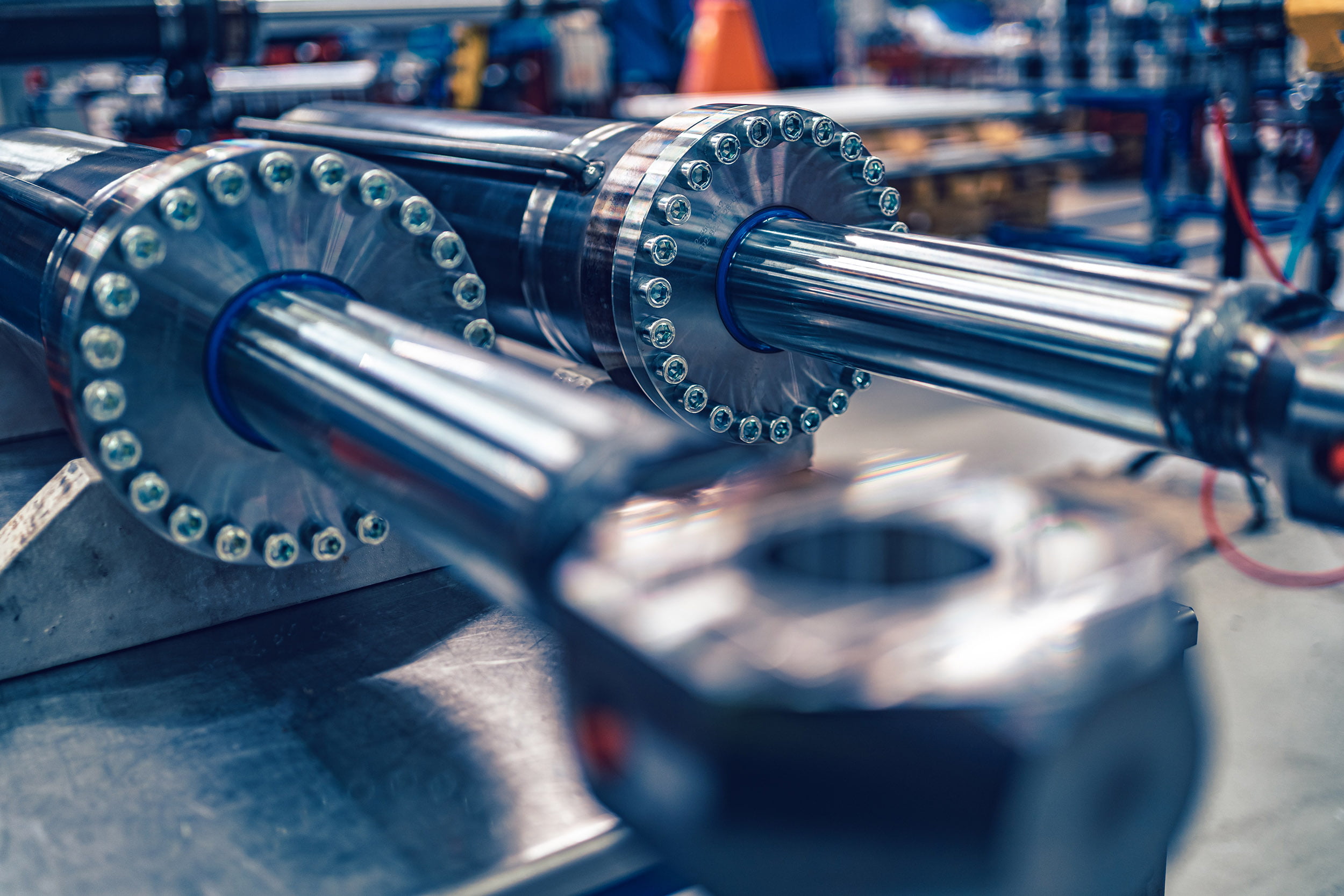

HYDRAULIC CYLINDERS

We’ve been manufacturing advanced, custom hydraulic cylinders for over 60 years. What can we help you power?

Hydraulic cylinder and connectivity solutions

for off-highway heavy equipment manufacturers

We build sophisticated custom hydraulic cylinders and develop monitoring solutions for off-highway mobile equipment. How can we help your business?

Hydraulic cylinder solutions

From our trusted, top-of-the-line, custom-tailored hydraulic cylinders to our efficient and flexible state-of-the-art manufacturing processes, Hydroline is ready to help with any industrial challenge that comes your way. We also support our customers with dedicated lifecycle services.

IoT & Connectivity

We are expert machinists, welders, technical specialists, consultants and robotics and machine learning engineers. We pioneer IoT and connectivity technologies and we are looking to the future with a strong focus on sustainably driven solutions. Need a monitoring solution for linear actuators? We can help.

OEM customer segments

We manufacture customized hydraulic cylinders for the most demanding industries in various customer segments. What segment do you operate in?

World’s leading manufacturers rely on Hydroline

Hydroline, a leading name in the hydraulic cylinder industry, stands out as a trailblazer in offering smart, innovative, and technologically advanced custom hydraulic cylinders for off-highway equipment manufacturers. With a commitment to exceeding customer expectations and a history of continuous innovation, Hydroline has become a trusted partner for companies seeking hydraulic solutions tailored to their specific needs.

Our dedication to innovation, customization, and reliability makes us an ideal partner for off-highway heavy equipment manufacturers. With a global reach and our focus on technological advancement, we continue to shape the hydraulic cylinder industry, empowering the world’s leading manufacturers to achieve peak performance in their machinery. In the world of hydraulic cylinders for heavy equipment, Hydroline stands as a symbol of excellence and innovation.

Your work powers ours

Hydroline pioneers custom hydraulic cylinders for off-highway heavy equipment manufacturers. And in heavy equipment manufacturing, durability, efficiency, and flexibility are paramount. There is rarely a one-size-fits-all solution. Being innovative and staying at the forefront of technology is how we help our partners succeed. That’s why industry leaders rely on Hydroline.

Our automated, fast, and flexible production capabilities are truly world-class. We excel in designing and manufacturing customised hydraulic cylinders that precisely meet your unique requirements. With our decades of innovation and commitment to excellence, Hydroline has become a trusted partner for companies seeking custom hydraulic solutions that are designed to perform reliably under the most demanding work conditions.

Our latest news

All newsHydroline’s CNC Operator Recruitment Training Program

23.02.2026

Hydroline’s CNC Operator recruitment training program is starting from February 23, 2026. To strengthen the future workforce and ensure long-term operational excellence, Hydroline has initiated..

Read moreHydroline welcomes Lars Hellberg to its Board of Directors

09.06.2025

We are thrilled to announce that Mr. Lars Hellberg has joined Hydroline’s Board of Directors. Lars strengthens our Board with his extensive industry experience and..

Read moreGabriela Łuczak appointed as Hydroline’s first ESG Manager

09.01.2025

Gabriela Łuczak Appointed as Hydroline’s First ESG Manager starting from January 1, 2025 Hydroline is proud to announce that Gabriela Łuczak, the former Quality Manager..

Read moreMeet Hydroline at Bauma 2025

04.11.2024

Come meet us in Bauma! We are happy to announce that Hydroline will be exhibiting in Bauma, the world’s leading construction machinery trade fair in..

Read moreNeed a hydraulics solution?

No question is too big or too small for our team of experts.

Just fill out our contact form and we’ll get back to you soon.

(*) indicates required field

Our blog – all you need to know about hydraulic cylinders

Hydraulic cylinders in forestry

15.12.2025

Forestry doesn’t wait. Whether it’s harvesting in the middle of a rainy autumn, clearing storm damage, or moving logs on frozen ground, the work goes..

Read moreHydraulic cylinders in agriculture and maintenance

20.11.2025

Every season brings new challenges to farms. Heavy soil in spring, long harvest shifts in autumn, or equipment that needs servicing in the depths of..

Read moreHydraulic cylinders in load handling

27.10.2025

From the forklift in a distribution center to the reach stacker in a busy port, hydraulic cylinders are the essential force behind the movement of..

Read moreHydroline’s ESG Commitment

29.09.2025

At Hydroline, sustainability is not just a responsibility but the foundation for our future as a trusted partner for the OEMs and a leader in..

Read more