Friction welding in hydraulic cylinder manufacturing

Do you know what is friction welding and why does is play a significant role in hydraulic cylinder manufacturing? There are several different types of welding which each have their own benefits, and there are even many different ways of doing friction welding as well. In this post we will focus on telling about the main principles of friction welding process, and we will also explain how it differs from traditional welding.

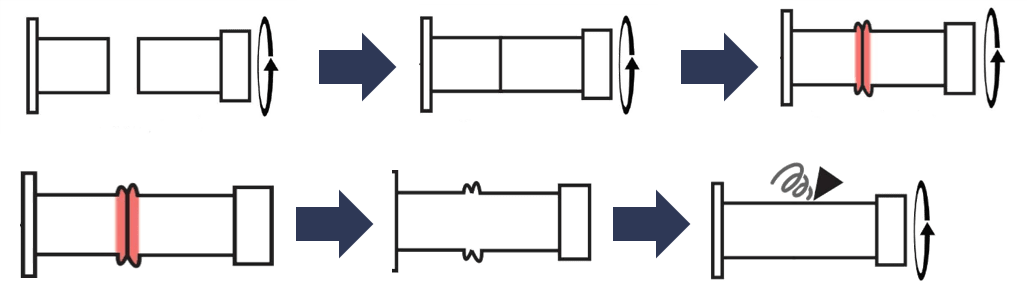

Friction welding is process known as solid state welding process. Solid state welding is a welding process that does not use external heat, unlike traditional welding where the welding is conducted with external heat. In solid state welding external pressure is applied to a stationary matter – such as a cylinder rod – to form the weld. In friction welding the two pieces that need to be joined are welded together with rotating movement. The rotation with hard force against each other creates friction. The friction then heats the materials at the contact surfaces.

Friction welding is also used in cylinder manufacturing at Hydroline. It is actually said to be the most cost-effective method of producing high integrity piston rod assemblies in high quantities. The friction welding project has been ongoing at Hydroline since 2012 and our first machine was acquired in 2015. Though it has not yet reached its full capacity as certain forms and elements are not usable for friction welding, it is extremely suitable for very demanding objects, such as boom cylinders and steering cylinders, as well as safety critical cylinders.

🔥 How does friction welding actually work?

In friction welding, two components are rubbed together at a controlled rotational speed. Although the term welding is used to define the process, it actually has no resemblance to conventional welding as there is not filler material involved. The other component stays on place and the other one is rotated as the components are brought together. When pressing the components together, this creates the fiction and the heat that allows both components to reach a plastic state and be forged together. Rotation is stopped and after that, some extra pressure is applied to the joint. With friction welding, a 100% welded, forged quality bond is achieved. As a final step, the machine removes the extra flash by lathing.

Illustration of friction welding process.

💙 Friction welding at Hydroline

At Hydroline, we are using friction welding in about 20 of our products. The method is extremely reliable and definite process as the component is welded completely through; did you know that in conventional welding when welding is done with wire, the structure cannot be welded all the way through.

At the moment, there are about 15 000 pieces around the world with friction welding manufactured by Hydroline. In case a customer wants their cylinder with friction welding, it needs to be taken into account in design phase as the component shortens a little bit with this method due to the material length loss that occurs in the process. By utilizing the expertise of our design department, the customer can be sure that the proper calculations have been made 100 % correctly and the final product with friction welding is made according to the customer’s needs and fits the exact measurements.

Usually, when new materials or size classes are used in the process, certain quality control researches are performed, metallurgical integrity and such. The researches are done in outside labs where the welded component is opened, and the connecting surface is investigated. Depending on the welded piece’s geography, also bending and tensile tests might be done.

⭐ What are the benefits of friction welding?

The benefits of friction welding are the material and production efficiency as the method creates a stronger connecting surface than conventional welding process. Friction welding also requires less raw materials, post-weld machining and preparation. As the method creates 100% bonds, it allows high strength join with superior, forged quality and small heat-affected zones on the components. The result in friction welding is also melt-free. The machine-controlled friction welding process is consistent and eliminates the human error: the parameters are easily controlled, repeatable and monitored all the way through. The process allows the joint of dissimilar materials which then allows the design of bimetallic parts. This provides flexibility in design. Friction welding also requires a smaller area for heat control as the heat-affected zone is smaller than in traditional welding.

The process itself is also much faster than conventional welding and only minimal post-weld machining needs make the component almost immediately ready for the next step in the overall manufacturing process. The process is also ecological as it is energy efficient and uses no gases, flux or filler materials. Material waste in the process is minimal and it creates no weld splatters. Therefore, friction welding is also an eco-friendly process because it does not create smoke or release harmful toxins.

Want to read more from us?

LEO: The predictive maintenance solution for hydraulic cylinders

27.06.2020

What is LEO, the predictive maintenance and monitoring solution for hydraulic cylinders? The project with LEO started already in 2013 when Hydroline presented the invention..

Read moreFully automated production line – the future of hydraulic cylinder manufacturing

21.10.2019

It is time to open a little bit about our project of our new automated manufacturing line for tubes and rods. The project kicked off..

Read moreHydraulic cylinder contract manufacturing

15.09.2021

Hydraulic cylinder contract manufacturing is a partnership that benefits both parties: the OEM customer and the hydraulic cylinder manufacturer. It offers a trusting relationship, which..

Read moreHydraulic cylinder manufacturing

11.03.2022

Like we have explained in our very first blog post, a hydraulic cylinder is one of the four main components of a hydraulic system. Hydraulic..

Read more