How do hydraulics work?

How do hydraulics work? For centuries people have known harnessing hydropower for everyday use. It is one of the most widely used and oldest forms of energy usage. Its applications range from watering to construction equipment and heavy machinery. It is so widespread that many households and offices may use hydraulic equipment daily. The engineers of the past built the basis for contemporary hydraulic systems to meet the needs of the modern world.

But who invented hydraulics then? Well, it is hard to determine who exactly invented the hydraulic systems, but hydraulic systems have been created based on the work of great minds like Leonardo da Vinci, Galileo Galilei, Blaise Pascal, and Joseph Bramah, just to name a few. Hydraulics found its place in the modern world during the industrial revolution offering wide-reaching and effective applications.

As the 20th Century began, the time had also begun for the new and varied uses for hydraulics. Nowadays, hydraulic systems are widely used because they of their are adaptability and their easy and flexible usage with many different actuator types. The high-power density is also one of the advantages a hydraulic system system offers. Aside from vehicle and industrial usage, you can find hydraulic systems everywhere: most sophisticated machinery where one can spot hydraulic systems includes machines such as airplanes, space shuttles and construction equipment.

|  |  |

What is a Hydraulic System?

Today, hydraulic systems can be found in a wide range of applications from small assembly processes to integrated steel applications and heavy machinery. Hydraulics enables the operator to accomplish significant work by lifting heavy loads, turning a shaft, drilling precision holes, and so forth with a minimum investment in mechanical linkage through the application of Pascal’s law.

A hydraulic press usually consists of a pair of cylinders, that are interconnected and filled with hydraulic fluid like oil. On the sides of these cylinders are installed two pistons that remain in contact with the fluid. When a certain force is applied in the smaller section of the piston, the pressure is transmitted throughout the fluid. According to the mentioned law of Pascal, the pressure will be identical to that exerted by the fluid in the other piston. For further information on how does a hydraulic cylinder work, read this blog post.

Hydraulic fluid creates fluid power by pumping the fluid through the hydraulic system. The fluid flows to the cylinder through the valve, and the hydraulic energy converts it back to mechanical energy. The valves aid to direct the flow of the fluid and the pressure can be relieved if needed.

The principle of Pascal’s law is realized in a hydraulic system by the hydraulic fluid that transmits the energy from one point to another. Because the hydraulic fluid is nearly incompressible, it can transmit power instantaneously.

A British mechanic named Joseph Bramah applied the principle of Pascal’s law and developed the first hydraulic press at the beginning of the industrial revolution. His hydraulic press was patented in 1795, widely known as the Bramah press. He figured that the pressure applied to a small area converts to a bigger force in the area that is larger on the other side of the cylinder.

How does a hydraulic system work?

The hydraulic system consists of five elements: the driver, the pump, the control valves, the motor, and the load. The engine may be an electric motor or an engine of any type. The pump acts mainly to increase pressure.

Hydraulic systems consist of numerous parts:

- The electric motor powers the hydraulic pump.

- The reservoir holds hydraulic fluid.

- The hydraulic pump pushes the fluid through the system and converts mechanical energy into hydraulic fluid power.

- The valves control the flow of the liquid and relieve excessive pressure from the system if needed.

- The hydraulic cylinder converts energy back into mechanical energy.

There are many types of hydraulic systems, but each of them contains the same main components as listed. All of them are designed to work the same way.

The science behind hydraulics – Pascal’s principle

The science behind Hydraulics is called Pascal’s principle. Pascal’s law or Pascal’s principle, the backbone of fluid-mechanics was discovered in 1653 and published in 1663 by Blaise Pascal. According to it, if the pressure changes at any point in the hydraulic fluid, the energy will be transmitted equally in all directions. When you apply pressure on the fluid, it will be distributed equally undiminished. The fluid pressure will be equal in all parts of the container.

According to Pascal’s principle, the pressure is equal to the force divided by the area on which it acts. A pressure used on a piston produces an equal increase in pressure on the second piston in the system. If the area is 10 times the first area, the force on the second piston is 10 times greater, even the pressure is the same throughout the cylinder. The hydraulic press creates this effect, based on Pascal’s principle. Pascal also discovered that the pressure at a point in a fluid at rest is the same in all directions; the pressure would be the same on all planes passing through a specific point.

Pascal Law Formula

Pascal discovered that a change in the pressure applied to an enclosed fluid is transmitted, without decrease, to each point of the fluid and to the walls of the container that contains it. This happens because the fluids are nearly incompressible, so when applying pressure, the fluid transmits it in all directions vertically to the walls of the container that contains them.

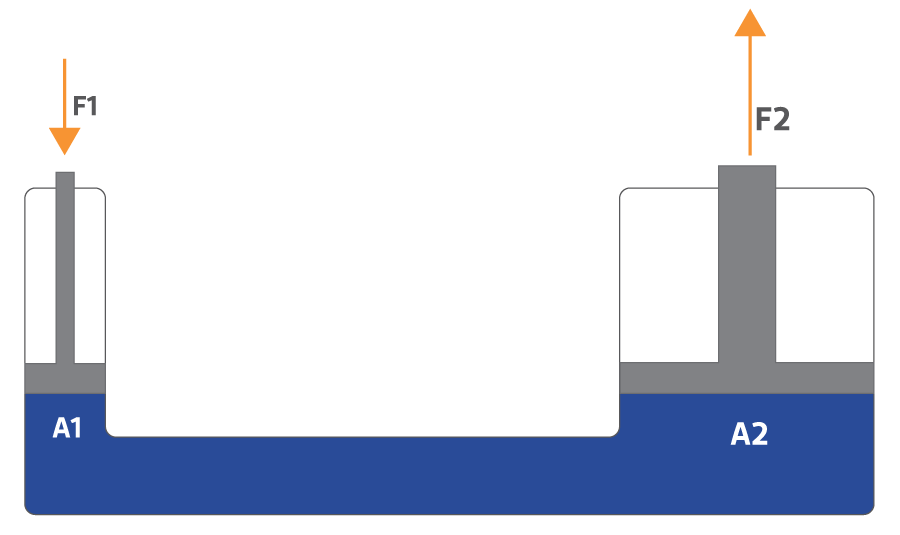

In this example case, a small force F1 applied to a small piston of area A1 causes an increase in the pressure in the fluid. According to Pascal’s principle, this increase is transmitted to a larger piston of area A2 by exerting a force F2 on this piston.

The pressure is the applied force over a surface as;

P=F/A >> F is the used force and A is the surface area.

There are two pistons on either side of the container, and the container is filled with incompressible fluid like oil. The pressure applied will be transferred equally and undiminished to all parts of the system.

For the first piston, a force F1 applied over a surface area A1. The pressure P1 is then: P1=F1/A1

The pressure P2 in the second cylinder with a force of F2 and surface area A2 will be: P2=F2/A2

When you apply pressure(P1) in the first piston, it will be equally transmitted through the confined incompressible fluid.

P1=P2

The hydraulic system allows the lifting of a heavy load with a small force. This equation shows that the force F2 is greater than the force F1 by a factor equal to the ratio of the areas of the two pistons. Note that the pressures in both pistons are essentially the same and as their areas are different, so are the forces, resulting in the ratio between their magnitudes equal to the ratio between their areas.

Blaise Pascal – Father of Hydraulics

Blaise Pascal (1623 – 1662) was a French mathematician, physicist, inventor, philosopher, and writer. He contributed significantly to science throughout his life. Pascal contributed to several fields in physics, most notably the fields of fluid mechanics and pressure. In honor of his scientific contributions, the unit of pressure (SI) and Pascal’s law has been named according to him. Pascal developed probability theory that was his most influential contribution to mathematics.

One of his most famous statements is known as the Pascal principle which refers that –

“The pressure exerted on a fluid that is not compressible and in equilibrium in a vessel with non-deformable walls is transmitted with equal intensity in all directions and at all points of the fluid.”

His work in the fields of hydrodynamics and hydrostatics centered on the principles of hydraulic fluids. He invented the hydraulic press, hydraulic pressure by multiplied force, and the syringe used in medicine. He proved that hydrostatic pressure depends not on the weight of the fluid but the elevation difference.

Pros and cons of hydraulic systems

Hydraulic systems are power transmission chains that convert mechanical energy into pressure and flow back into mechanical-movement again. Generally, the initial mechanical-energy is a rotational movement that is created with an internal combustion engine or an electric motor. The transmission of pressure and flow is created with hydraulic oil, and the final movement can be either rotational or linear movement.

The hydraulic system benefits are:

- Hydraulic systems are self-lubricating

- Good power to weight ratio

- Relatively small components

- Easy and flexible transfer of energy with hydraulic pipes

- Possibility to remove the actuation from hydraulic power generation due to easy transfer of hydraulic energy

- The hydraulic systems can be controlled either manually or with modern electronics.

The hydraulic system weaknesses are:

- The cleanness of transmission fluids

- The temperature dependant characteristics of fluids

- Long-distance power transmission causes power losses in the system

- The components and hydraulic fluids require maintenance at regular intervals

What is the future of Hydraulics?

We can be sure that hydraulics will be a large part of the machinery for the next Century ahead or even longer because it’s difficult to predict the technologies that will surface as we advance exponentially forward. For example, absolutely nobody predicted the Internet in 1950 and now we are still waiting for the flying cars and colonization of Mars, which may be closer than we think if we ask Elon Musk to predict these facts.

Have you stumbled upon the term “electro hydraulics“? What if you combine computers with hydraulics? Computers will be installed on the hydraulic equipment frequently in the future. This will assure accurately distributed control. Think about what this will mean for motors, cylinders, valves, and pumps. Electro hydraulics is making its way to modern hydraulics.

Hydraulics have a tremendous concentration of power. We refer to it as power density. Matching hydraulics for the brawn and computers for the brain makes hydraulics smarter and more efficient. Electronics can’t match it, at least not yet. What electronics can provide is far better coordination and control.

Get yourself ready for hydraulic equipment with an ever-higher IQ powered with AI shortly. Considering the ever-evolving and rapid technology development, hydraulic equipment is becoming ever more powerful. Unfortunately, operator skills aren’t developing at the same rate and that is why more user-friendly equipment is needed urgently. For the safety of the operator and the long-term viability of the equipment, the design of hydraulic equipment is going to have to be more user-friendly. The challenge will be to make the hydraulic equipment itself more skillful. AI-powered hydraulics will accomplish this challenge.

Market-leading innovations with hydraulics

The growth of hydraulic technology since the 19th Century has been phenomenal. The main advantages of hydraulic systems are the easy and powerful energy transfer, flexible, and customized properties, and ability to multiply force-transmission in a variety of industrial uses. Hydraulic systems are successfully used in the operation and control of machine tools, farm -, construction -, and mining machinery as well as automobile and aircraft industries. Without a doubt we can say, the fluid power can compete successfully with mechanical and electrical systems. Hydraulic power systems can provide forces from a few kilos to thousands of tons.

As technology development is evolving rapidly in the modern world and the variety of hydraulic-power systems are getting more specific and customized to many industries, there are still many possibilities to develop hydraulic use further. Hydraulic-power systems have become one of the major players in hydraulic energy-transmission technologies widely used in industrial, mining, forestry, aircraft industries, and even in space technology. Hydraulic-power systems are widely used in automobile technology in the brakes, steering mechanisms, and their transmissions. Industrial automation and mass production utilize the foundations of hydraulic-power technology as well.

As the space race continues to evolve, hydraulic systems play a major role there as well.

The hydraulic industry is becoming more and more proactive. The needs of the customers are changing and evolving into more complicated and specific requests. We love new challenges and we are ready to solve them for you. We at Hydroline make sure to provide the services you need also in the future.

More interesting posts from us 💎

How does a hydraulic cylinder work?

12.06.2019

How does a hydraulic cylinder work? As we have written in our first blog, a hydraulic cylinder is one of the four main components of..

Read moreHow to design a hydraulic cylinder?

17.02.2021

How to design a hydraulic cylinder? The hydraulic systems date back as far as over 4,000 years ago in Ancient Egypt. They initially applied the..

Read moreCleanliness in hydraulics

03.03.2021

Did you know that maintaining fluid cleanliness in hydraulic systems can cut operational costs by up to two-thirds? Clean systems do not only lead to..

Read moreGravimetric analysis in hydraulic cylinder manufacturing

01.06.2020

Gravimetric analysis in hydraulic cylinder manufacturing process? In our previous blog post, we told you about the hydraulic cylinder assembly and as we mentioned in..

Read more