Different types of hydraulic cylinders

Harnessing the fluid power in motion is not a new invention. Fluid power has been a powerful energy source for thousands of years. Initially, water was turning wheels and pushing levers. Since those times, hydraulics has evolved in the last century to what we know as fluid power today. The primary fluid power principles still apply, relying on pressurized fluids to produce powerful forces to lift massive loads.

In 1648, French physicist Blaise Pascal realized that pressure on a confined fluid exerted an equal force in all directions and could be harnessed to lift heavy loads.

Almost a hundred years later, in 1738, Daniel Bernoulli invented pressurizing water in pumps and mills, using the so-called Bernoulli principle. And in 1795, the first hydraulic press was patented by an English scientist Joseph Bramah. His patent paved the way for the industrial revolution to automate factories. Over time, engineers discovered that water wasn’t the best solution for hydraulic pumps and motors due to the corrosive features and implementation of oil was introduced for hydraulic systems.

Oil was a perfect solution for the non-corrosive and denser properties, and it could handle heavier loads. Oil was resistant to evaporation and remained cooler under the high pressures of hydraulic forces. As fluid power evolved, so did hydraulic cylinders with materials, applications, mounting configurations, and internal designs developed further.

A massive shift to advanced hydropower technology has evolved in the last 100 years. There has been a significant advancement in hydraulic cylinders working on construction technology, aircraft and space shuttle development, marine technology, drilling, mining, forestry, and manufacturing industries.

Hydraulic power can provide up to ten times more power compared to electric motor power. Fluid power applications are ideal for pushing, pulling, and lifting massive loads. Nowadays, the new technology allows it to be precisely controlled, and the safety aspects of the technology make it even more compelling equipment.

Hydraulic power systems are currently widely used in many industrial applications and developed further with new technology. Hydroline is excited to be revolutionizing this over 2000-year-old technology. Our expert team of engineers is working daily to enhance the technology and provide purpose-built customized solutions for your service.

Many industrial sectors use hydraulic cylinders, including construction, automotive, aerospace, forestry, mining, marine, and manufacturing. When linear pressure is required in a machine, hydraulic cylinders are a perfect choice. Hydraulic cylinders are reliable workhorses that operate efficiently in many industrial contexts and require comparatively little maintenance. Hydroline manufactures customized hydraulic cylinders for agriculture, mining, construction, forestry, and vehicles.

The most essential information in this blog post:

Different types of hydraulic cylinders

What kind of hydraulic cylinder is required?

The most common types of hydraulic cylinders

Hydroline’s solutions are tailored to fit your needs

Different types of hydraulic cylinders

There are several types of hydraulic cylinders that you may encounter. Hydraulic cylinders are commonly used in applications that move heavy loads and require a significant amount of force. Hydraulic cylinders are simple, durable, and create a massive amount more force than pneumatic, mechanical, or electrical systems. In comparison, a hydraulic pump has about ten times the power density of an electrical motor’s similar size. There are an impressive array of cylinders available to choose from to meet the wide range of industrial demand.

Selecting the right kind of cylinder for an application is critical. That means taking into consideration several parameters. Fortunately, there is an assortment of cylinder types, mounting techniques, and “rules of thumb” available to guide you.

What kind of hydraulic cylinder is required?

There are few necessary details to consider when starting a design project for a custom cylinder. The first thing is to understand the operating environment in which the cylinder will be working. Factory environments most often are stable and working steadily compared to forestry environments, where the cylinders may encounter the risk of rupture.

When designing hydraulic cylinders for various environments, one has to remember that some cylinders are designed to last 50 000 cycles as others are designed to last a million cycles. It depends on the customer’s specification of what the cylinder’s lifetime needs to be.

The frequency of cylinder use is one of the critical factors to consider. How many cycles does the cylinder operate daily, monthly or yearly use? Does the cylinder constantly run during the day or just occasionally?

The pressure variations impact hydraulic cylinders’ fatigue life and are one of the significant factors to consider. The pressure rises and lowers smoothly in steady work, but the pressure variation might have massive regulations in a cycle work. For example, in a forestry machine, the pressure variation should be considered because the environment is changing. It might cause pressure peaks to the hydraulic cylinder due to stumps and fallen trees.

The most typical hydraulic cylinder configurations

The crucial measurements for all types of cylinders include stroke, bore diameter, and rod diameter. Stroke lengths vary from a few centimeters to several meters. Bore diameters can range from a few centimeters up to more than two meters. Piston rod diameters range from 1,5 centimeters to more than 50 centimeters.

For tie-rod cylinders, increasing the bore’s size also means increasing the number of tie rods needed to retain stability. Increasing the bore of the piston rod’s diameter is an ideal way to compensate for higher loads. Still, space considerations may not allow this, in which case multiple cylinders may be required.

The tie-rod, welded, and ram cylinder configurations are the most typical styles. Tie-rod cylinders use high-strength threaded steel tie-rods to provide additional stability. Welded cylinders have a barrel welded directly to the end caps. Ram cylinders use a high pressure pushing straight ahead. Ram cylinders are primarily used in heavy-duty applications.

The most common types of hydraulic cylinders

All hydraulic cylinders create linear movement, but different varieties have their unique effects. Below are some of the most common types of hydraulic cylinders.

Single acting hydraulic cylinder

Single-acting cylinders operate only in one direction, so the oil has only one access port into the cylinder. The port is located at the head end of the cylinder, which can only function in one direction. When the oil is pumped into the port, it pushes the rod, causing it to extend—the rod returns for an external force such as the load or a spring. As oil is pushed through, the port is pressed on a plunger and causes the movement. When the cylinder gets empty of oil, the plunger returns itself to the original position.

Advantages for the single-acting cylinders are that they have compact and space-efficient sizes and simple structures. Single-acting cylinders are easy to maintain, reliable in function, and have substantial pressure and force potential. Single-acting cylinders are economical and the most straightforward designs.

Disadvantages for the single-acting cylinders may be that those equipped with retractable springs are vulnerable to component failure as the springs wear out. The wear manifests as a gradual reduction in force on the retracting movement. They are also difficult to seal and can become damaged over time through exposure to corrosive fluids. Single-acting cylinders are primarily used in construction plants, internal combustion engines, reciprocating engines, pumps, hydraulic rams, and jacks.

The single-acting, spring-loaded cylinders function with the internal spring that controls the piston’s flow and the single port’s fluid. The seals at the head of the piston stop the fluid from reaching the spring. This feature ensures the spring and the fluid can function together in different directions, with additional forces being applied from either side. These cylinders are primarily used to push and pull when required. They can also be mounted vertically to allow the piston’s weight to contribute to the cylinder’s function.

Single-acting vs. double-acting

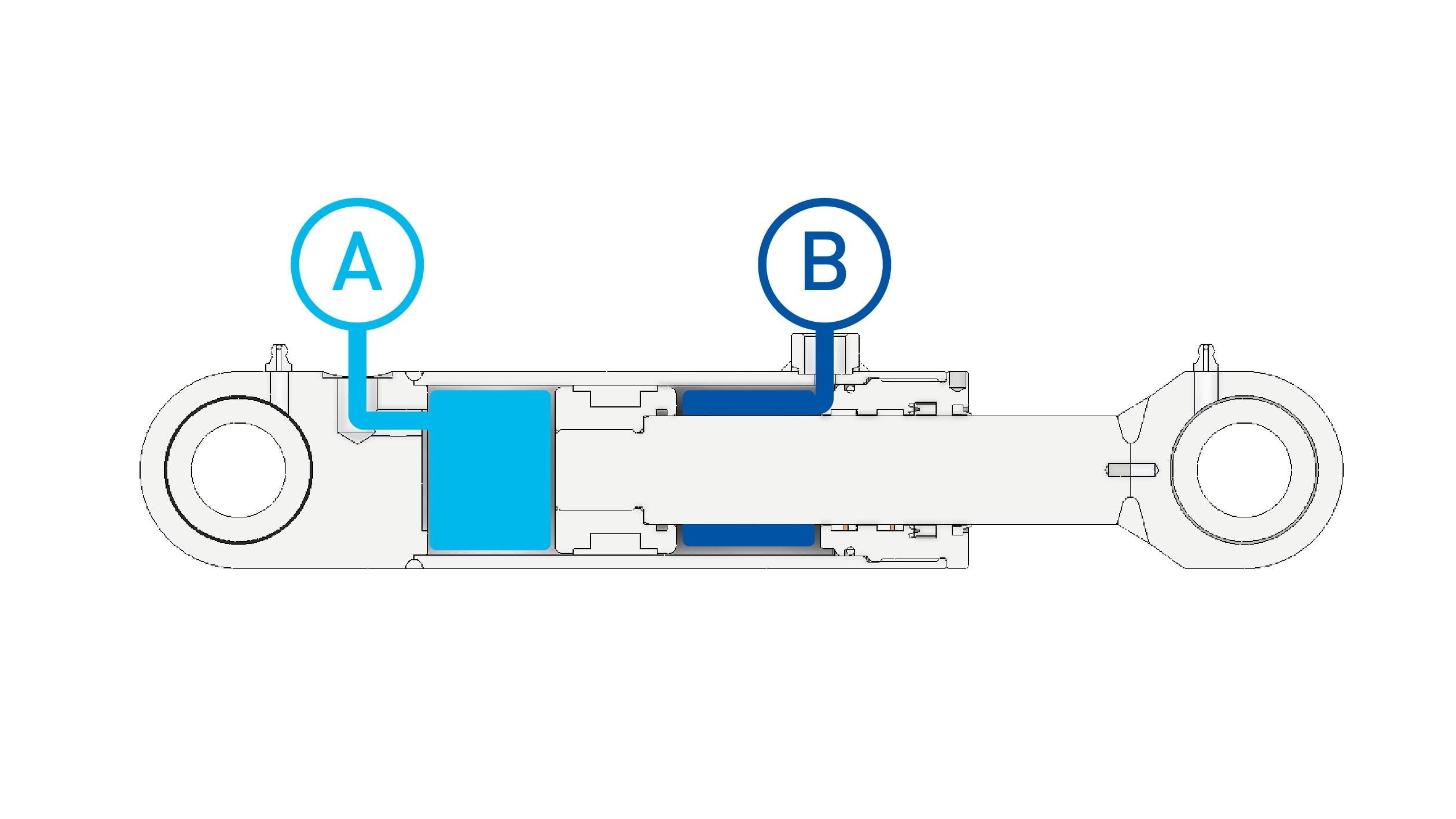

Single-acting and double-acting cylinders are the two most commonly used types of hydraulic cylinders. What is the difference between these two types of cylinders? The simple answer is that a double-acting cylinder has both an A and a B Port. Oil enters the cylinder via A port, which pushes the piston down. Oil diverts to port B when the piston’s control calls to retract, pushing the piston up. We have also written a blog post about the differences between single-acting and double-acting hydraulic cylinders, you can read it here.

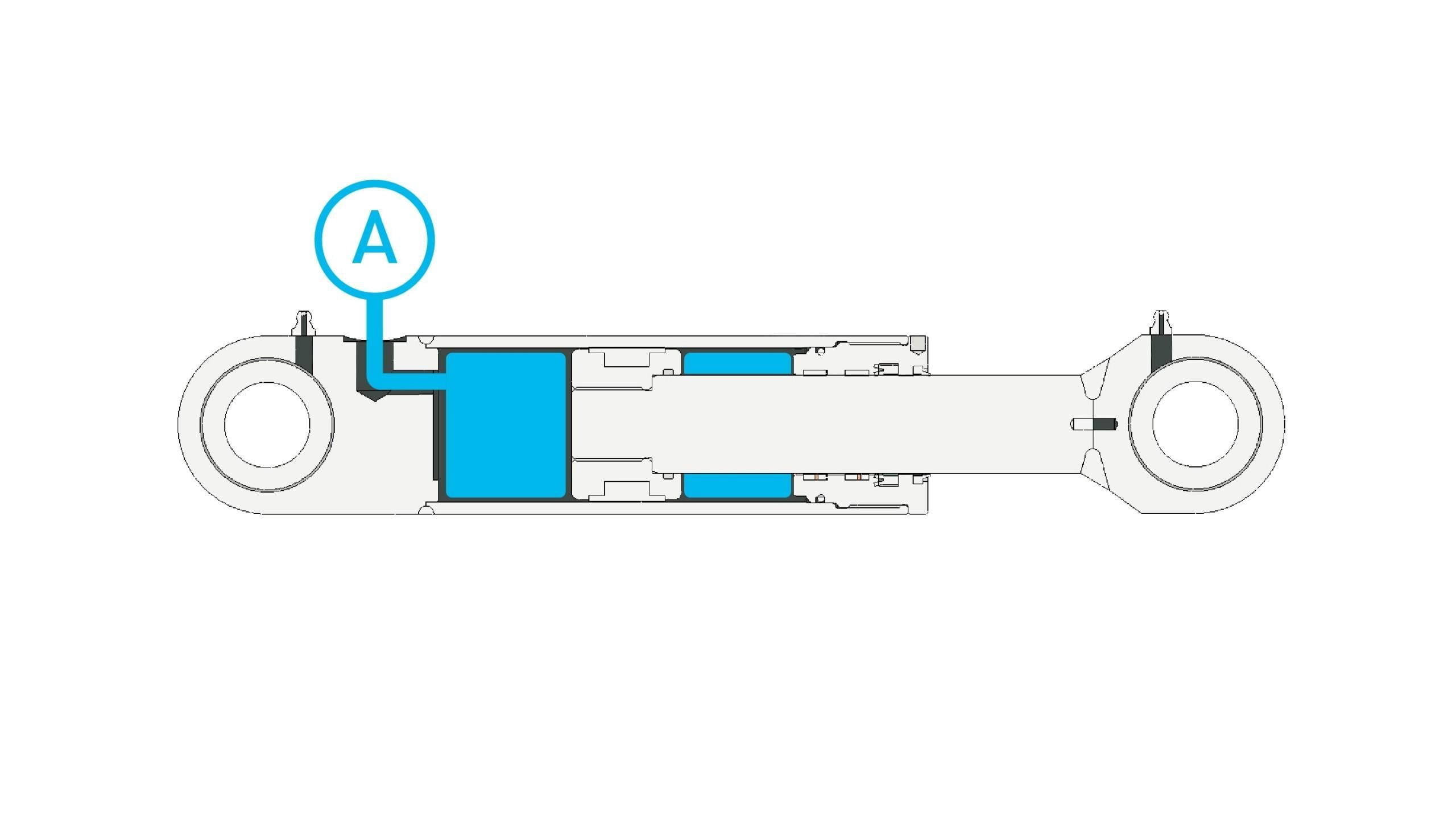

An illustration of a single-acting hydraulic cylinder |  An illustration of a double-acting hydraulic cylinder |

Double-acting hydraulic cylinders

Unlike the single-acting cylinder, the double-acting cylinder has two ports; one for extending the plunger and another for retracting. These ports are positioned at either end of the cylinder, the head, and the rod. Both ports are used when retracting the rod, as a rod is extended and a port at the head end is simultaneously used.

Double-acting cylinders have a crucial advantage over other types of cylinders. A ram lip’s presence allows the rod to be additionally supported within the cylinder throughout the extending and retracting processes.

A double-acting cylinder is capable of pressure being exerted on either side of the piston alternatively. The outward and retraction movements can be achieved without external power sources when the cylinder is under pressure. The pressure can return the piston to its starting position or apply an alternating force on both sides of the cylinder to operate a crankshaft.

The advantages of double-acting cylinders are that they are easily accessible because they are the most commonly used hydraulic cylinders. They are rugged, reliable, and save energy. Double-acting cylinders need fewer hydraulic fluids, have controlled acceleration, and perform well repetitively accurately. Double-acting cylinders have precisely definable stroke measurements and have a massive variety of potential applications.

Double-acting cylinders are used primarily in large-scale engines, like ship motors, industrial furnaces, digging machines, lift shafts and steering mechanisms.

Balanced, double-acting, piston-type cylinder

An extra-long piston with a clevis allows for careful yet precise changes to the cylinder’s pressures and balances without interfering or disrupting the cylinder’s other parts and mechanisms. This cylinder has a steel ring seal and ports at either end. The configuration of the piston is different, with access at only one end.

Non-differential cylinder

The non-differential cylinder has two ports, similar to the double-acting cylinder. The main difference between these two is that the rod is extending from both ends. It makes the cylinder more stable and can be measured in terms of speed and thrust placed on the rod within the cylinder.

When the flow can move from end to end of the rod, it makes it an unusual cylinder compared to other designs. It is usable in many different ways but challenging to use, for example, in mobile equipment. The seal, piston, and steel ring provide control and stability to manage the conditions inside and balance the forces.

Telescoping, ram-type, actuating cylinder

Telescopic cylinders are designed with a series of steel or aluminum tubes of progressively smaller diameters nested within each other. Telescopic cylinders can be single or double-acting. In general, telescopic cylinders are more expensive than standard cylinders. Most telescopic cylinders are single-acting, and double-acting telescopic cylinders are specially custom designed and manufactured. Telescopic cylinders are multi-stage units of two or more steps.

This type of cylinder is very different from the other designs. It functions in a very compact structure. Rams placed closely alongside each other to form collective cylinder units. These units work together with one or two ports to control the fluid flow. In this design, the rams and the ports are all contained with the cylinder’s housing. A substantial advantage of this design is the cylinder’s reach when all the rams are extended together.

Tie rod cylinder

Tie rod-style hydraulic cylinders use high-strength threaded steel rods to hold the two end caps to the cylinder barrel. These designs are often used in industrial factory applications. Small-bore cylinders usually have four tie rods, and large bore cylinders may require up to 16 or 20 tie rods to retain the end caps under the forces produced. Tie rod-style cylinders can be completely disassembled for service and repair and are not always customizable.

|  |

Welded body cylinder

Welded body cylinders have several advantages compared to tie rod cylinders. Welded cylinders have a narrow body and often a shorter overall length, enabling them to fit better into tight machinery confines.

Welded cylinders function efficiently due to tie rod stretch at high pressures and long strokes. The welded cylinder is customizable, and unique custom features can be easily mounted to this cylinder design. The welded cylinders are the perfect design for multi-stage telescopic cylinders due to their smooth surface.

Welded hydraulic cylinders dominate the mobile hydraulic equipment market. Construction equipment, excavators, bulldozers, road graders are all using welded design cylinders. Also, material handling equipment such as trucks, lift-gates, and telehandlers have welded cylinders. A heavy-duty industry like cranes, oil rigs, and large off-road vehicles for above-ground mining operations are widely using welded cylinders.

Tandem hydraulic cylinder

In a tandem hydraulic cylinder, there are two interconnected cylinders that operate together. This generates a greater force than one cylinder would create on its own. Tandem hydraulic cylinders’ general applications include fork lift trucks, elevated work platforms, cranes and barges.

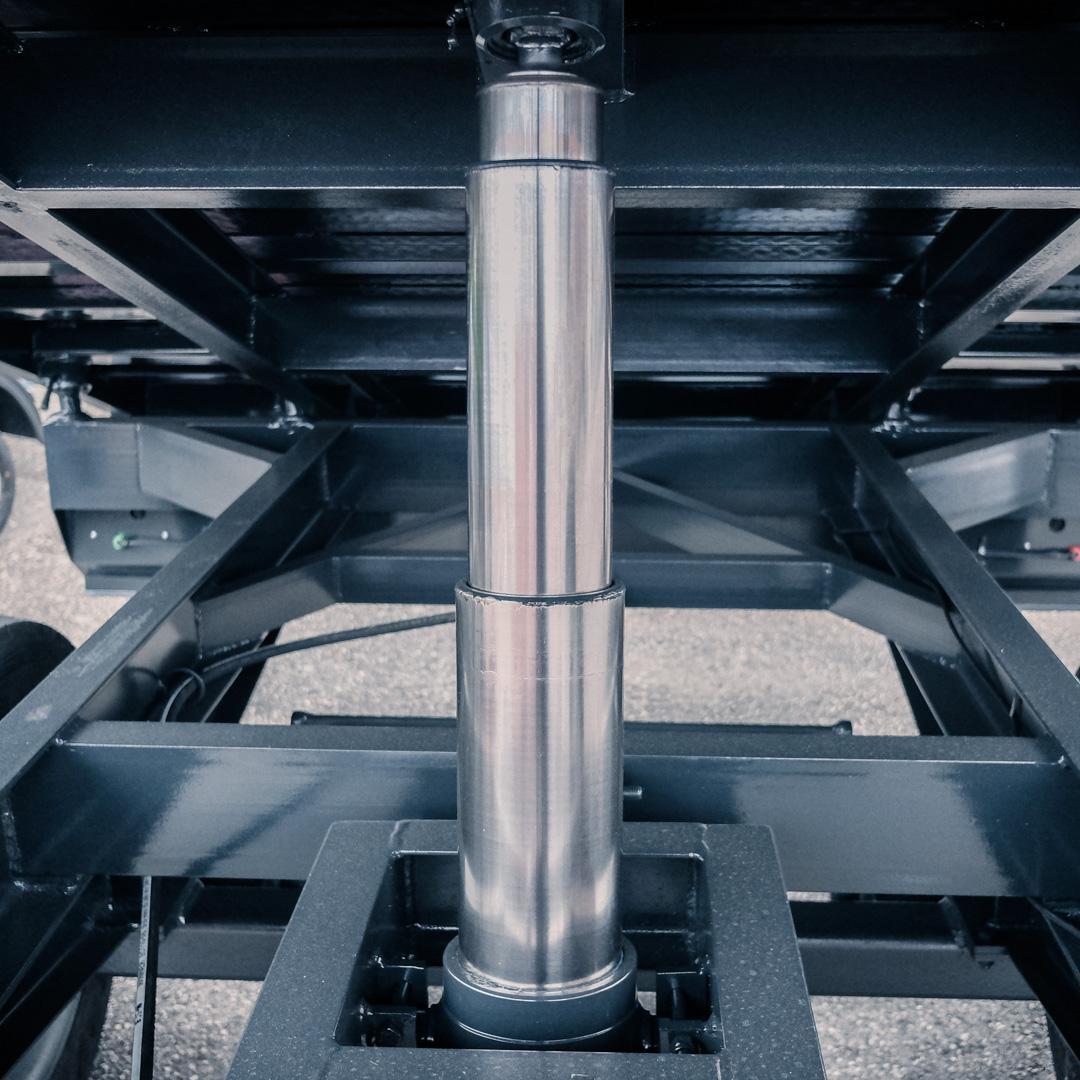

Tandem hydraulic cylinders are used for example in fork lifts. Tandem hydraulic cylinders are used for example in fork lifts. |  Single-acting hydraulic cylinders only need to create force into once direction Single-acting hydraulic cylinders only need to create force into once direction |

Cushioned Cylinder

The cushioned cylinder is designed with cushioned padding to prevent the piston’s stroke from being too strong and stabilizing the cylinder’s pressures. The metering device inside the cylinder controls and restricts the piston’s power when operating and creates the cushioned effect results.

Differential cylinder

A differential cylinder acts as a standard cylinder when pulling. However, if the cylinder has to push, the oil from the cylinder’s piston rod side doesn’t return to the reservoir but goes to its bottom. Differential cylinders are manufactured as standard cylinders.

Plunger cylinder

A plunger cylinder is a design without a piston or with a piston without seals. This cylinder can be used only for pushing. The maximum force this cylinder creates is the piston rod area multiplied by pressure. This means that a plunger cylinder has a relatively thick piston rod.

Position sensing intelligent hydraulic cylinder

The intelligent position sensing hydraulic cylinders eliminate the need for a hollow cylinder rod. An external sensing bar senses the cylinder’s piston’s position by placing a stable magnet within the piston. The magnet spreads a magnetic field through the cylinder’s steel wall, providing a sensor locating signal.

Reliable, high-quality custom hydraulics systems are essential to keep your machinery running at peak efficiency. Poorly designed hydraulics systems will lead to higher operational costs and lost income due to downtime. Working with an experienced custom hydraulic specialist is essential.

Hydroline’s solutions are tailored to fit your needs

High-quality manufacturing for customized hydraulic cylinders forms the foundation for our business operations. We produce high-quality hydraulic solutions considering the environmental and sustainable aspects of our operations.

We practice efficient and sustainable use of materials and energy. Our goal is to minimize the environmental impact and encourage all our partners to participate with us against global warming. A sustainable future, global environmental issues, and high-quality conscious production are the heart of our business operations.

At Hydroline, we have the experience, infrastructure, and capacity to fulfill all your hydraulic engineering needs, conserve resources, and improve efficiency. Choosing the best hydraulic partner will help you to streamline your operations and improve profitability. Hydroline has over 50 years of experience in custom hydraulic cylinders with a passion and focus on reliability and concentrate on your success.

Whether you have questions concerning hydraulic cylinders or looking for a high-quality hydraulic design to suit your needs, Hydroline can help. We supply customized heavy-duty and industrial hydraulic cylinders to suit your specific application requirements.

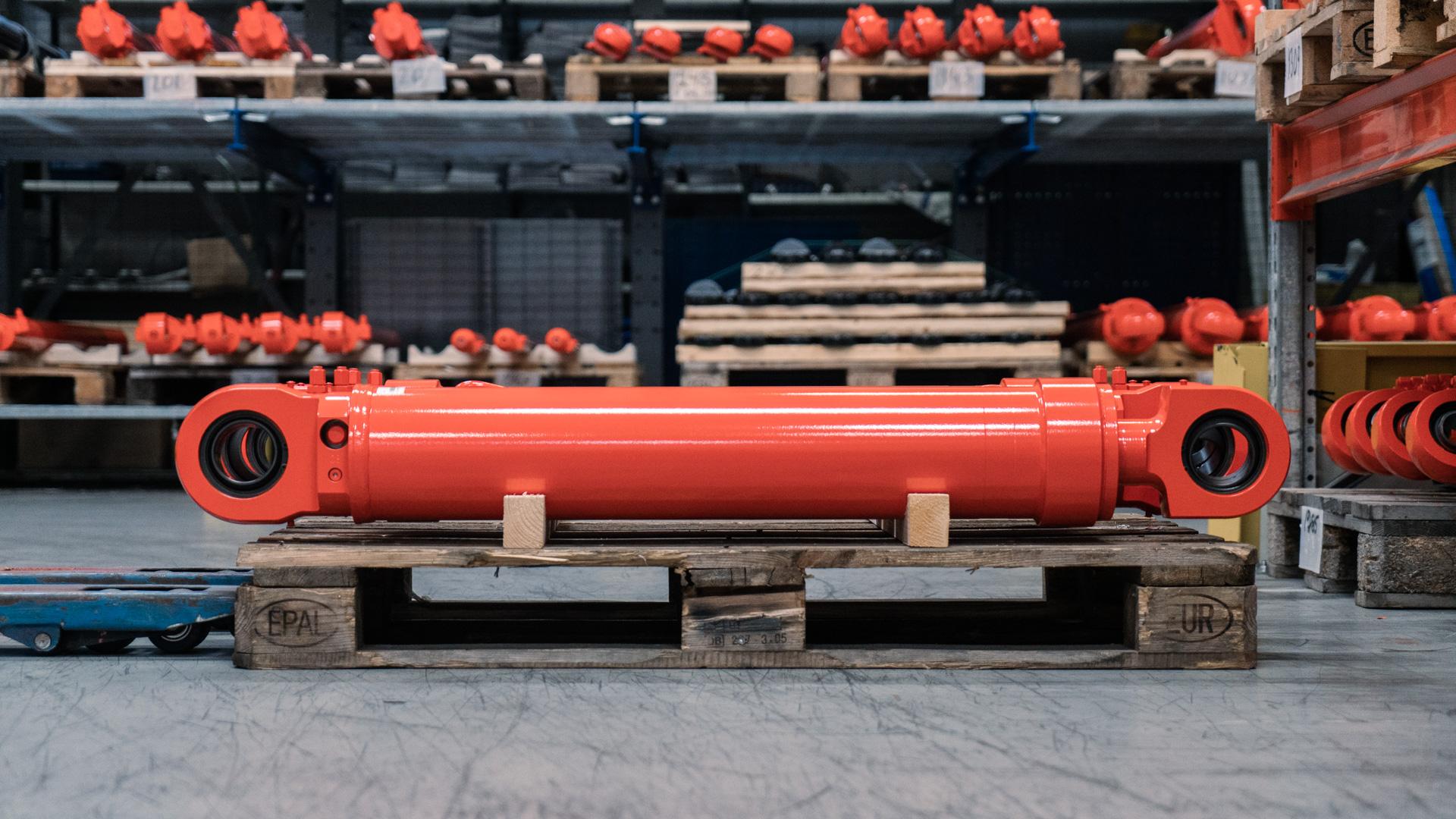

|  |